In-cycle spline milling saves production costs

By A Mystery Man Writer

Last updated 07 Jul 2024

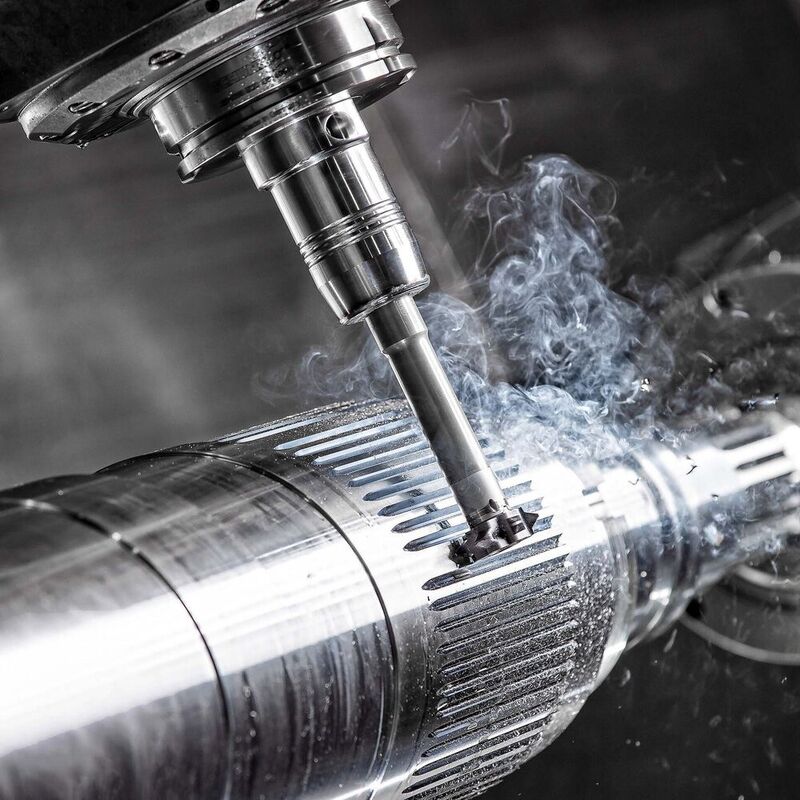

(Bild: Horn/ Sauermann) Tooling manufacturer Horn highlights one of its customers that is saving costs by not only turning a drive shaft on a multi-tasking CNC lathe but also milling a spline in the same set-up, an operation that was previously subcontracted out.

Valve Seat Tooling, Machine Tooling

Modular reamers for large bores - MTDCNC

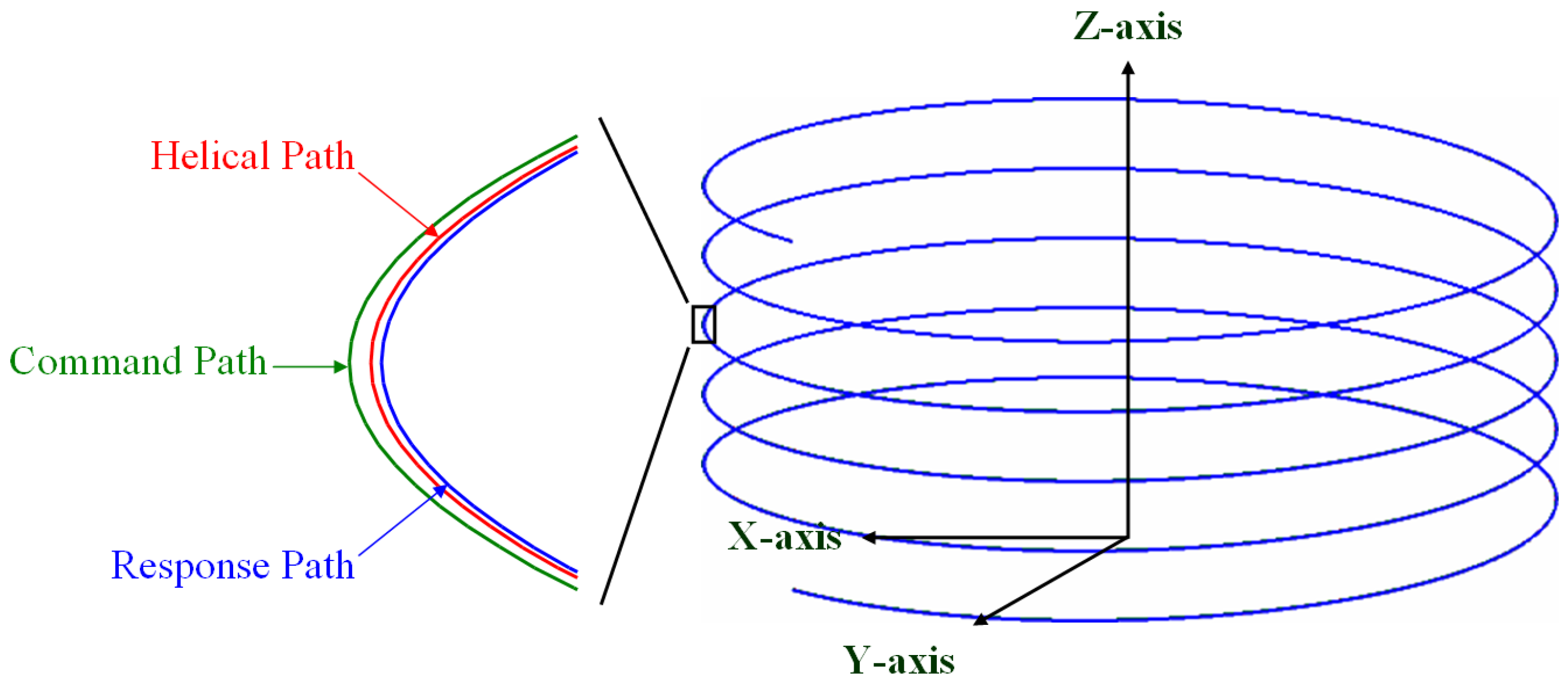

Applied Sciences, Free Full-Text

Custom carbide form tools for turning – MTDCNC

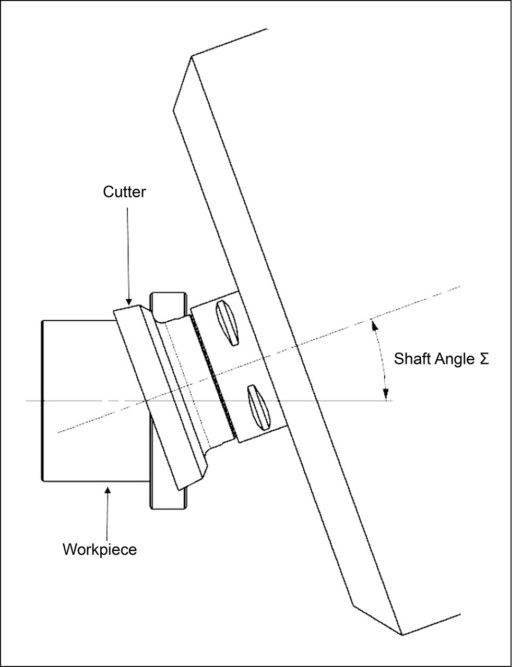

Gear Skiving—A Step Changing Manufacturing Process Applicable to Multifunctional 5-Axis Machine Tools

Manufacturing Machinery World December 2022

Industry Nine Hydra - MTN - MS - Freehub Complete Kit w/ 12mm DS Endcap : Sports & Outdoors

5 Axis CNC Machining: Types, Applications, Benefits, and Design

Pratt Whitney Spline Mill (1 of 2) Milling Machine (still under power)

Mill-Turn Programming Software Solutions

Recommended for you

You may also like

:max_bytes(150000):strip_icc()/Best-Candles-IS-tout-c7e170fd36cf4daa95219691e9905dea.jpg)