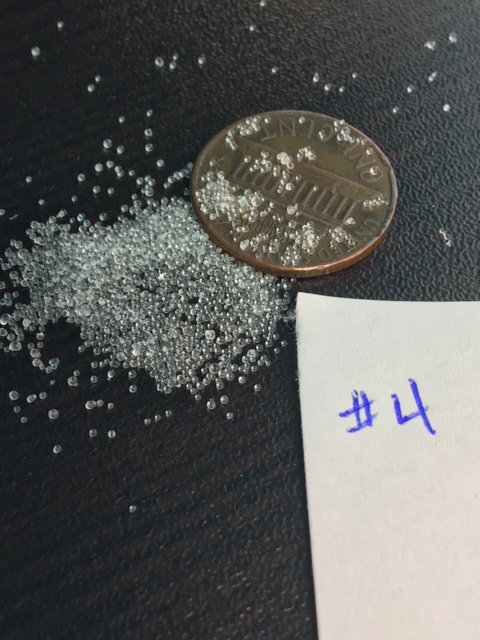

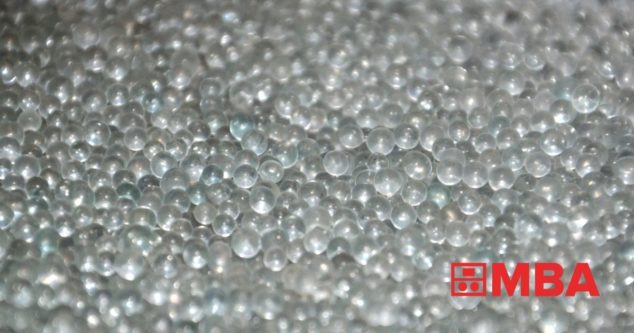

Glass Bead Blasting: Abrasive Shape, Hardness & Recycle Rate

By A Mystery Man Writer

Last updated 14 Jul 2024

Of all abrasives, glass bead blasting is arguably the most popular and the easiest on equipment. This is partly due to the versatility of glass beads.

Glass Beads Media Abrasive

Sandblasting - Wikipedia

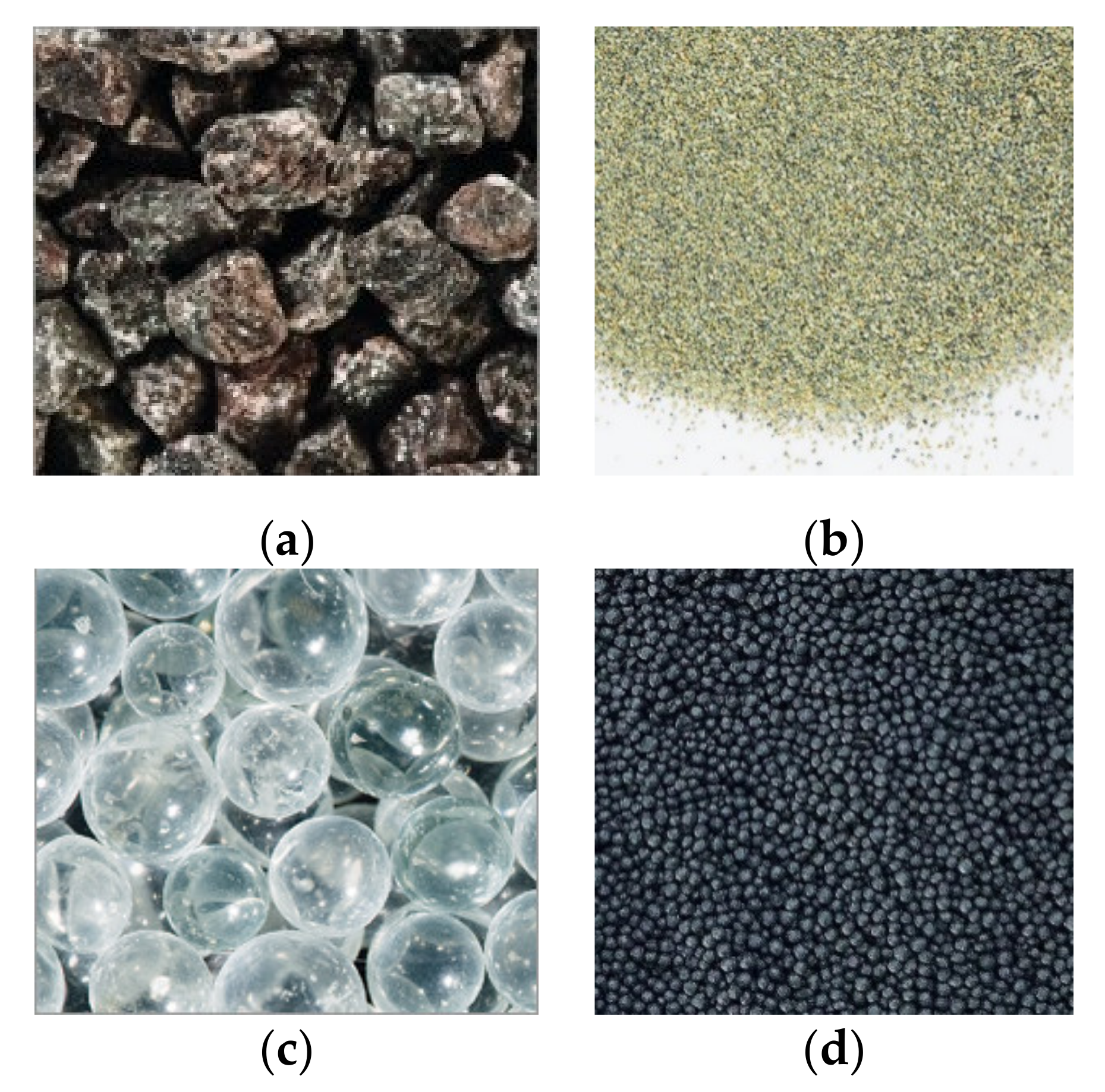

Metals, Free Full-Text

Understanding Abrasive Blast Media Restoration & Remediation Magazine

Sodium Bicarbonate – The Softer Blasting Abrasive – ARMEX Soda Blasting Media

What Blast Media Should I Use In A Wet Blast Cabinet? - Quantum Blast Technologies

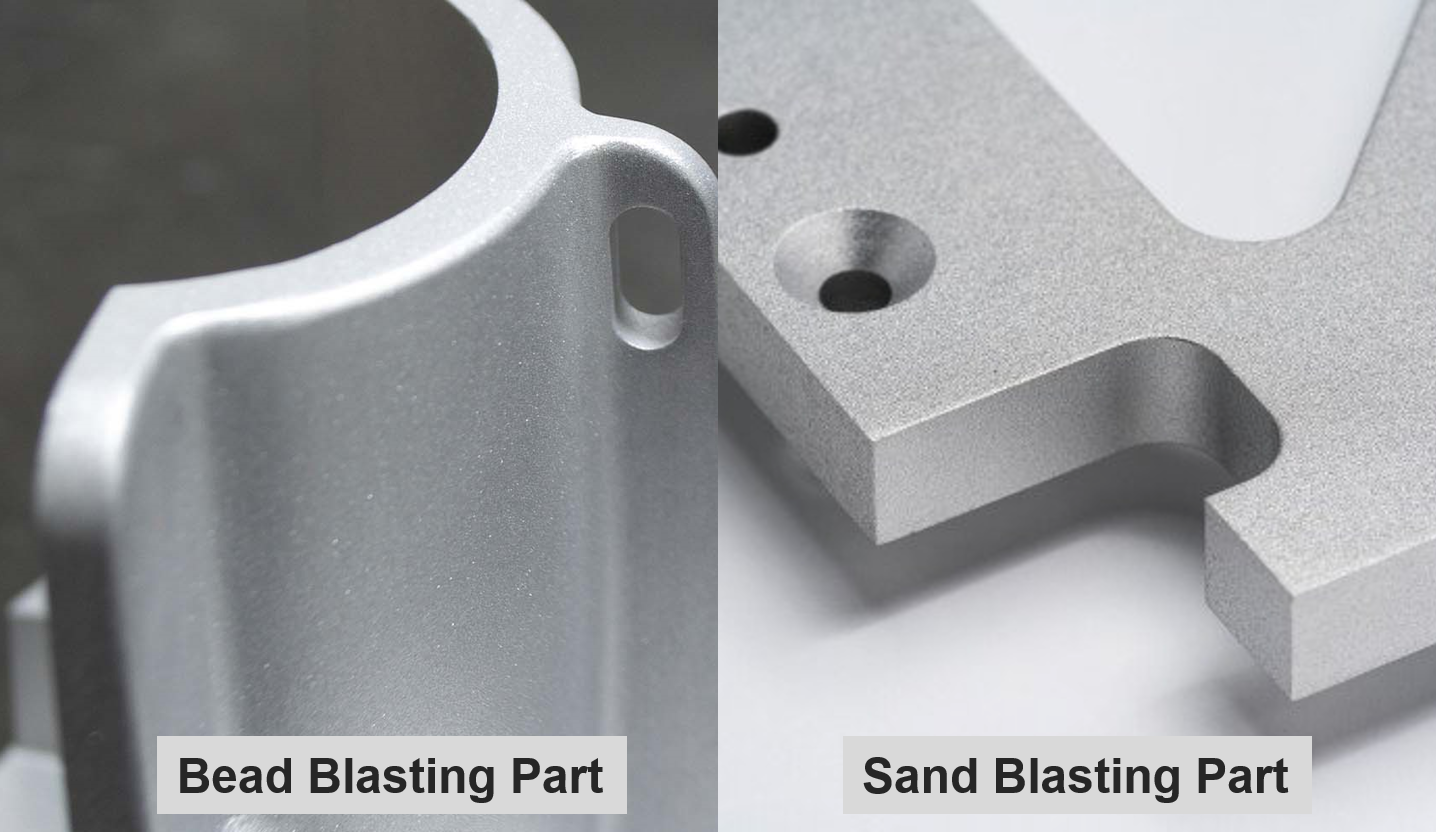

Comparing Bead Blasting and Sandblasting: A Detailed Guide - CNC Machining Service, Rapid prototyping

Recycling Abrasive in Blast Cabinets - A Guide

Bead Blasting Overview - LEADRP - Rapid Prototyping And Manufacturing Service

Recommended for you

You may also like