Energy-Saving Compressed Air Resin Dryers

By A Mystery Man Writer

Last updated 16 Jul 2024

Introduction Resin drying is a critical step in the manufacturing process of injection molding, extrusion molding and stretch blow molding. Compressed air resin dryers are one of the most commonly used dryers in the plastics molding industry. Recent advancements in compressed air membrane-type resin dryers, have reduced the associated energy costs significantly. Multiple NovaDrier Compressed Air Resin Dryers using Membranes from Novatec In plastics manufacturing, plastic resin material must be free of moisture before it is processed to ensure that the end product is defect free. †Many of today’s plastic resins are hygroscopic. If the moisture is not properly removed it will boil off when heated during the molding or extrusion process. This released vapor can cause both structural and cosmetic flaws in the finished product. Most plastic resins, such as PA (Nylon), PC and PET, are hygroscopic materials. They adsorb moisture from humid ambient air and give moisture back to dry air. Every type of resin can hold a specific amount of moisture between its molecular chains. Additional amounts of moisture can be condensed on the surface of the pellets (surface moisture). Non-hygroscopic resins, such as PE, PP and PVC, do not adsorb any moisture, but they still can have surface moisture. Adsorbed moisture in hygroscopic resins and surface moisture in non-hygroscopic resins are known to cause defects in molded plastics and they might lead to a complete production stop (source: www.fasti.com). 80% of Problems in PET Manufacturing are Linked to the Drying Process Wellman Inc. is a leading PET resin manufacturer. Their PermaClearÆ PET packaging resin is used in the manufacture of plastic beverage bottles and other food packaging containers. They claim that 80% of problems in PET manufacturing are linked to the resin drying process. This is due to the fact that PET (polyethylene Teraphthalate) is a very hygroscopic material - meaning it absorbs water into the molecular structure. The moisture absorption occurs through exposure to the environment during transit and storage. Proper drying means a proper resin. To insure molecular weight retention and optimum properties, it is recommended that PET must be dried to less than .005 % moisture (0y weight %) prior to melting in the extruder. If excessive moisture is present, hydrolysis will occur during the molten state and will reduce molecular weight. This reduction in molecular weight will result in several changes in the PET preforms. The most notable will be greater than normal intrinsic viscosity (IV) losses and the increased rate of crystallization that will reduce clarity and cause haze in the preform.

ESM Series - Energy Saving Air Dryers

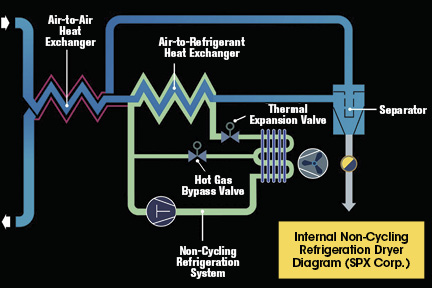

Compressed Air Dryer : An All Inclusive Guide

Product Category: Drying

Saving Dehumidifying Drying System Plastic Resin Dryer

Dryers – Dri-Air Industries, Inc

What Are Membrane Air Dryers?

Dryers – Dri-Air Industries, Inc

XD 20 SERIES - Drying Systems

Drying Equipment for Plastics Processing

Compressed Air Dryer Efficiency - Fluid Power Journal

Recommended for you

You may also like

![Skycase Microfiber Towels for Cars,[5 Pack]Professional Premium All-Purpose Microfiber Towels for Household Cleaning Car Washing,Highly Absorbent,LINT-Free,Cleaning Towels (15.7x15.7),Blue](https://i5.walmartimages.com/asr/1590fc54-1858-46ea-8a81-1eb4b2f4cbab.a66aa7b0a17a52516fc9e41664872523.jpeg?odnHeight=768&odnWidth=768&odnBg=FFFFFF)